Floatation Dryers

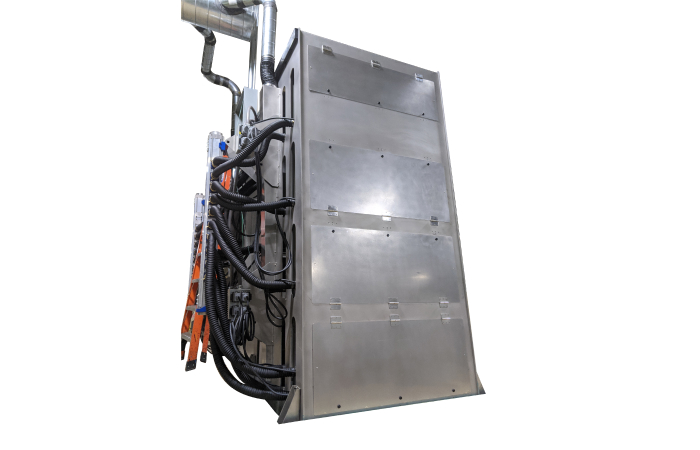

Converting processes applying extremely heavy functional coating layers for pressure sensitive adhesive products, painted sheet metal, photographic films and similar niche processes take high performance drying to the next level. Practical solutions include applying heating from both sides of the web doubling the injection of energy compared to single sided dryers.

To stabilize the web handling of the webs, traditional floatation dryer manufacturers staggered the nozzle resulting with a sinusoidal pattern as the web travels through the dryer. Floatation dryers commonly recirculate massive volumes of air consuming copious amount of energy.

FlexAir technologies can be configured for aggressive backside heating while relatively gently removing the vapor laden boundary layer from the coated side of web and replacing the boundary layer with fresh hot and dry air.

Using significantly lower volumes of supply air requires modest heating compared to traditional forced air drying technology. FlexAir technology delivers a continuous supply of dryer air ready to absorb moisture evaporating from the coatings. Recirculating the moisture saturated exhaust stream as an exercise of energy efficiency is neither practical nor necessary.