Extended Dryers

Highly integrated converting lines integrate numerous processes into a single stream combining multiple webs, printing technologies, and other converting processes. Extended dryers involve challenging drying of heavy coatings, slow curing processes and/or high temperature applications.

Extended Dryers differ from Tower Dryers primarily in their shape as the particular converting operation may not allow the print to physically contact mechanical devices while it is transported to another operation at some significant distance.

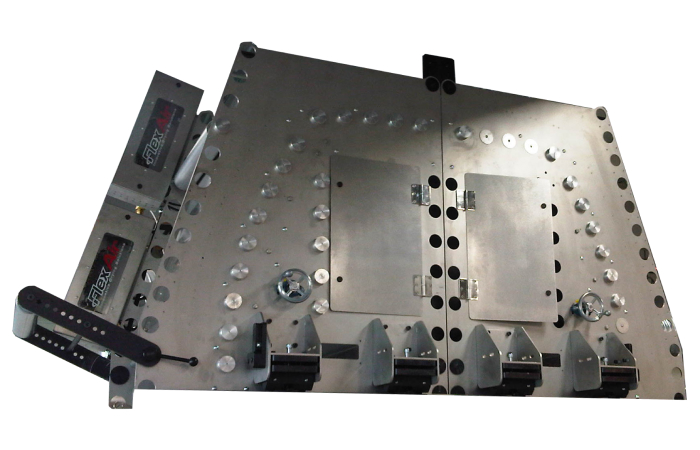

FlexAir C-Class and A-Class technologies provide unique modular solutions to profile the drying process through the stages of evaporation and curing. Given the generally small mechanical profile and exceptional drying effectiveness of FlexAir technologies the physical size of FlexAir Extended Dryers are significantly smaller and shorter than other forced air drying technologies. The cost of operation of FlexAir systems can be pivotal in the overall success of converting challenge.

Extended Dryers: Key Design Features

- Multi-zone temperature and pressure control.

- Reconfigurable Air Bar or Nozzle designs

- Managing complex web path requirements.